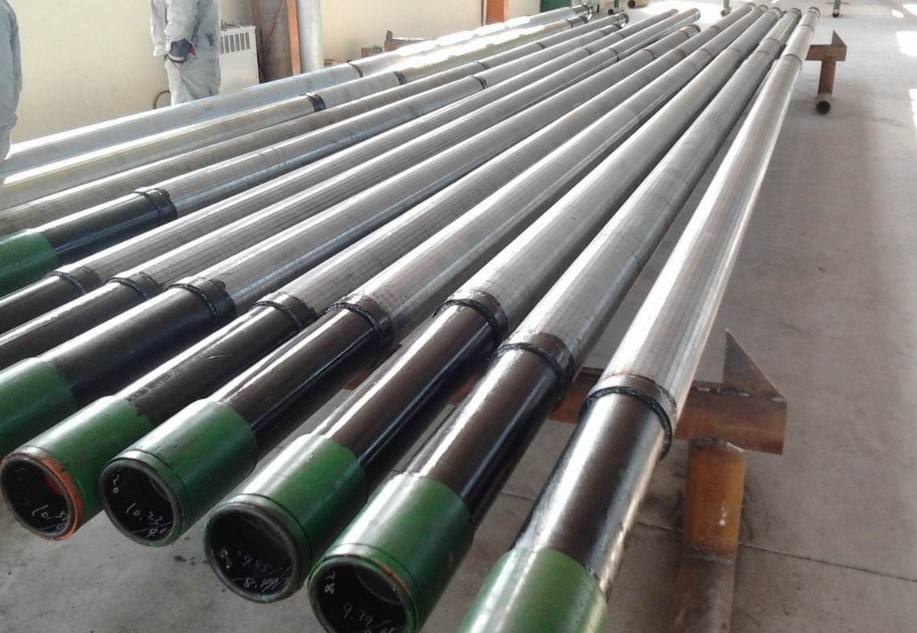

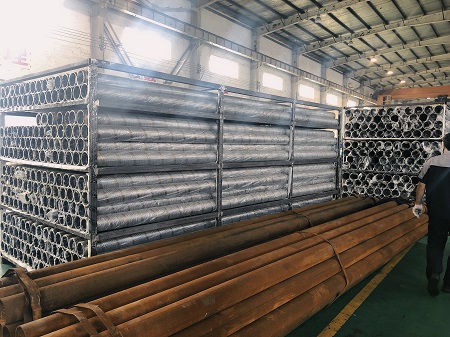

Oil screen Petrolume scren Casing tubing

The primary function of the oil screen is sand control, and the grade and type of steel used varies

depending on the geological environment (lithology) in which the well is located.

Additional information

| Keywords | Oil screen Oil casing Screen |

|---|---|

| Grade | J55 N80 P110 |

| Size | OD: 4 1/2’’ ~ 20’’ (114.3mm ~ 508mm) |

| Thread Type | NU EU BTC SC LC |

Product Details:

Types of oil screen tubes

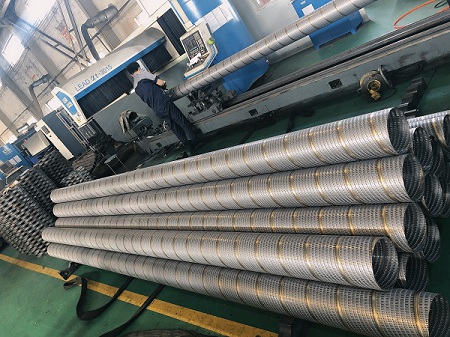

1. Slotted screen

2. Drilled screen

3. Wrap the wire screen

4. Bridge screen

5. Composite screen

Characteristics of oil screen

1. Oil screen adopts J55 or N80 oil casing body processing, high strength, not easy to deformation

2. Good verticality of the cutting edge, smooth cutting edge, no burr, even cutting seam.

3. Large flow area, 27/8 “screen tube 300 slits /1.5m, flow area 72 per cubic centimeter, 2.4 times larger than the same specification tubing flow

area.Good for liquid flow.

4. Its advantages are more obvious in deviated and horizontal Wells.

5. The overall anti-corrosion treatment, the formation of a dense protective layer on the surface of the screen, improve the corrosion resistance and wear resistance of the screen, can effectively extend the life of its underground work.

6. It is suitable for sand control of sand producing Wells with sand particle size greater than 0.3mm.

7. Simple operation, easy to use, large inner diameter, easy to configure the pipe stringIV.

Main technical parameters of oil screen:Type of pipe: oil casing, oil pipe;Tube length (single root) : ≤15m;Tube diameter: 50 ~ 500mm (length

≤15m),Wall thickness: ≤20mm;Width of seam :(0.10 ~ 4) mm±0.03mm;Number of slits: arbitrary;Cloth seam type: parallel, staggered,

spiral;Shaft surface seam spacing: arbitrary.