Your Reliable Manufacturer of Blast Joint in China

- 2000+ International Projects

- Maximize your prduction with our qualityier

- 15 years industrial experience with skilled workers

Oil Blast Joint

An oil blast joint is a critical component in oil and gas production strings, typically installed above the pump. Its core function is to significantly reduce the direct impact of high-velocity fluids on the tubing and casing through internal labyrinth flow channels or throttling designs. This effectively mitigates erosion and wear, thereby extending the service life of the string.

This device is particularly suitable for high-yield wells or sand-producing gas wells. It enhances production safety, reduces maintenance costs, and serves as an important tool for ensuring the long-term stable operation of oil and gas wells.

Strict quality testing

A rigorous inspection process is crucial for oil blast joints. It begins with a thorough visual check for any surface defects or damage. Dimensional accuracy is then verified using calibrated gauges to ensure it meets exact specifications. Finally, non-destructive testing (NDT) methods, such as magnetic particle or ultrasonic inspection, are employed to detect internal flaws like cracks or inclusions hidden within the material, ensuring structural integrity for safe operation.

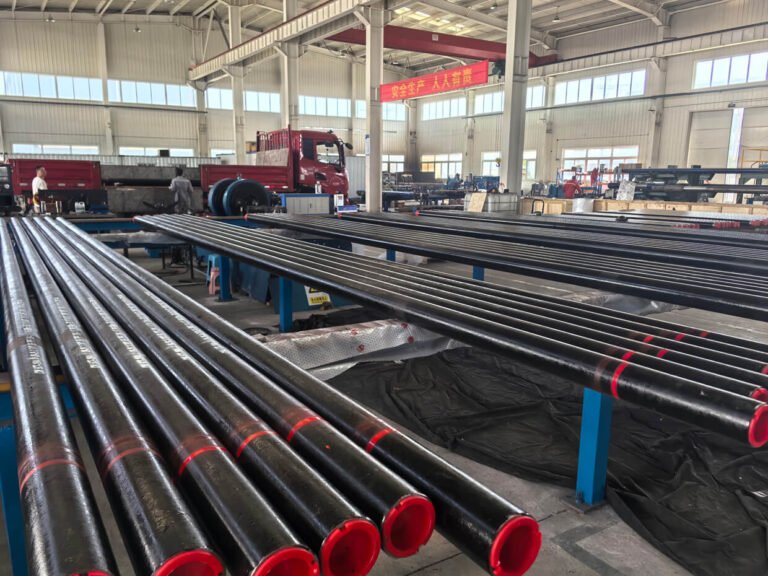

Advanced production technology

Our factory specializes in manufacturing high-performance oil blast joints, utilizing advanced production technologies. The precision machining and specialized heat treatment applied to each oil blast joint ensure exceptional resistance to erosion and high pressure. This guarantees product reliability and an extended service life in demanding downhole environments, making our oil blast joint a trusted component for critical oil and gas operations.

Blast Joint Production Process

Our products are manufactured through a precise, quality-controlled process, ensuring durability, reliability, and compliance with API standard from raw materials to final packaging.

Raw Materials

We carefully select raw material manufacturers that meet API standards and fully comply with inspection criteria before making any purchases.

Factory visit

We conducted on-site inspections of the selected factories, visually inspected the raw materials, and then signed contracts.

Purchase and delivery

After procurement, raw materials enter the factory, where each piece undergoes individual testing for appearance, wall thickness, and material properties to ensure that every piece meets API standard requirements.

Production scheduling

After the raw materials inspection confirms there are no issues, the production department then creates a production plan to ensure timely delivery to the customer and guarantee the product's production efficiency.

Production and processing

During the production process, we ensure that every step is strictly in accordance with API standards. We have a production team with 15 years of experience.

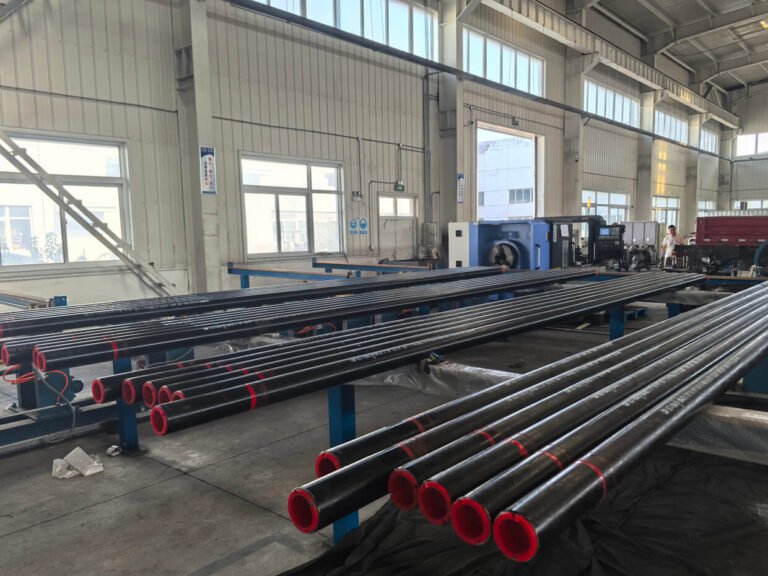

Finished product inspection

After production is completed, quality inspectors need to inspect each finished product according to API standards to ensure that every product meets the product standards.

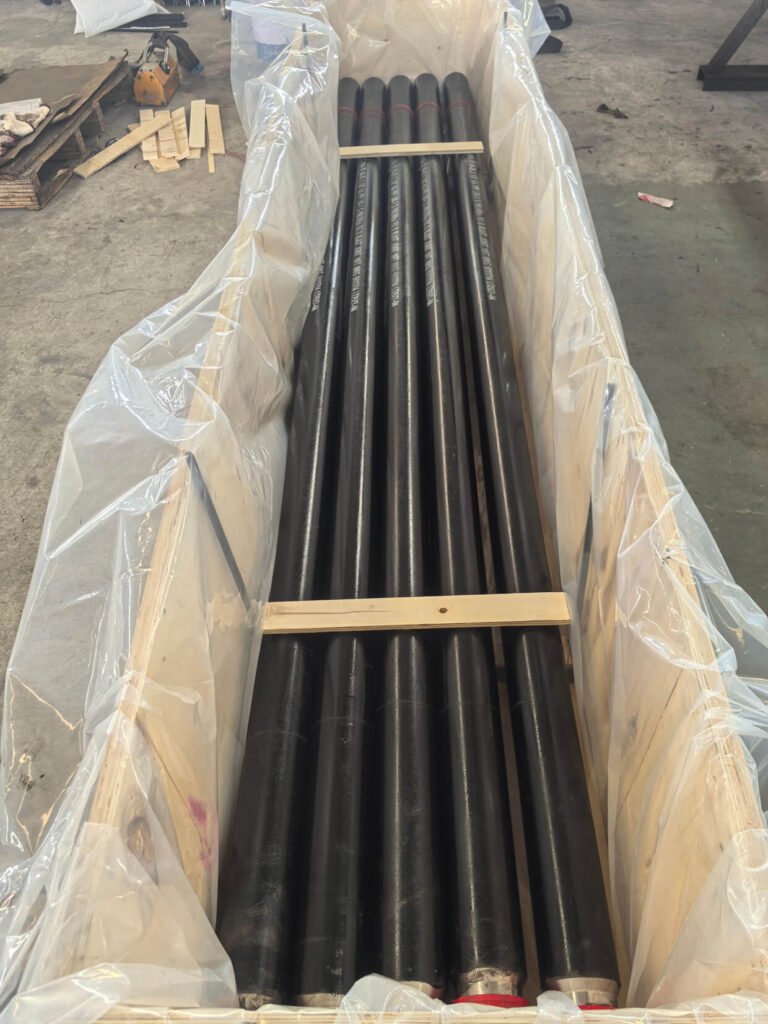

Product Packaging

After passing quality inspection, all products are packaged according to requirements for ocean shipping to ensure product protection during transit.

Packaging & Shipping

After packaging, the goods need to be transported to the port, where port staff will load them into containers, thus beginning their ocean voyage to the customer's port.

Quality Inspection

QA - 1

We verify the grade of raw materials and strictly measure the outer diameter and wall thickness before procurement.

QA - 2

The oil blast joint appearance and length of the raw materials must also be strictly controlled.

QA - 3

During the production process, every oil blast joint must be manufactured in strict accordance with API standards.

QA - 4

After each completed oil blast joint is inspected, a final visual inspection is required after packaging to ensure no damage to the tube body occurred during the packaging process.

Order Process

Inquiry & Quote

We will provide a quote immediately upon receiving your inquiry.

Confirm Order & Deposit

Pay a 30% deposit after order confirmation.

Production & QC

Production is carried out strictly in accordance with production requirements and a rigorous inspection process.

Shipping & Balance Payment

The remaining balance will be paid upon product completion, and ocean shipping will commence.

After-sales Support

We will provide technical support after the customer receives the product.

Contact Us

Let's Get Started

we are happy to hear from you and will reply to your with our product solutions.

Technology & Innovation

We can integrate resources from all over China, and we possess advanced thread processing technology to provide you with feasible solutions.

Proressional Expert

With 15 years of manufacturing experience, we can provide high-performance products, and our technical team can provide you with excellent technical support.

7/24 Online Service

Our customer support team is available 24/7 to assist with inquiries, technical questions, and product support.